Optical Device

Products

-

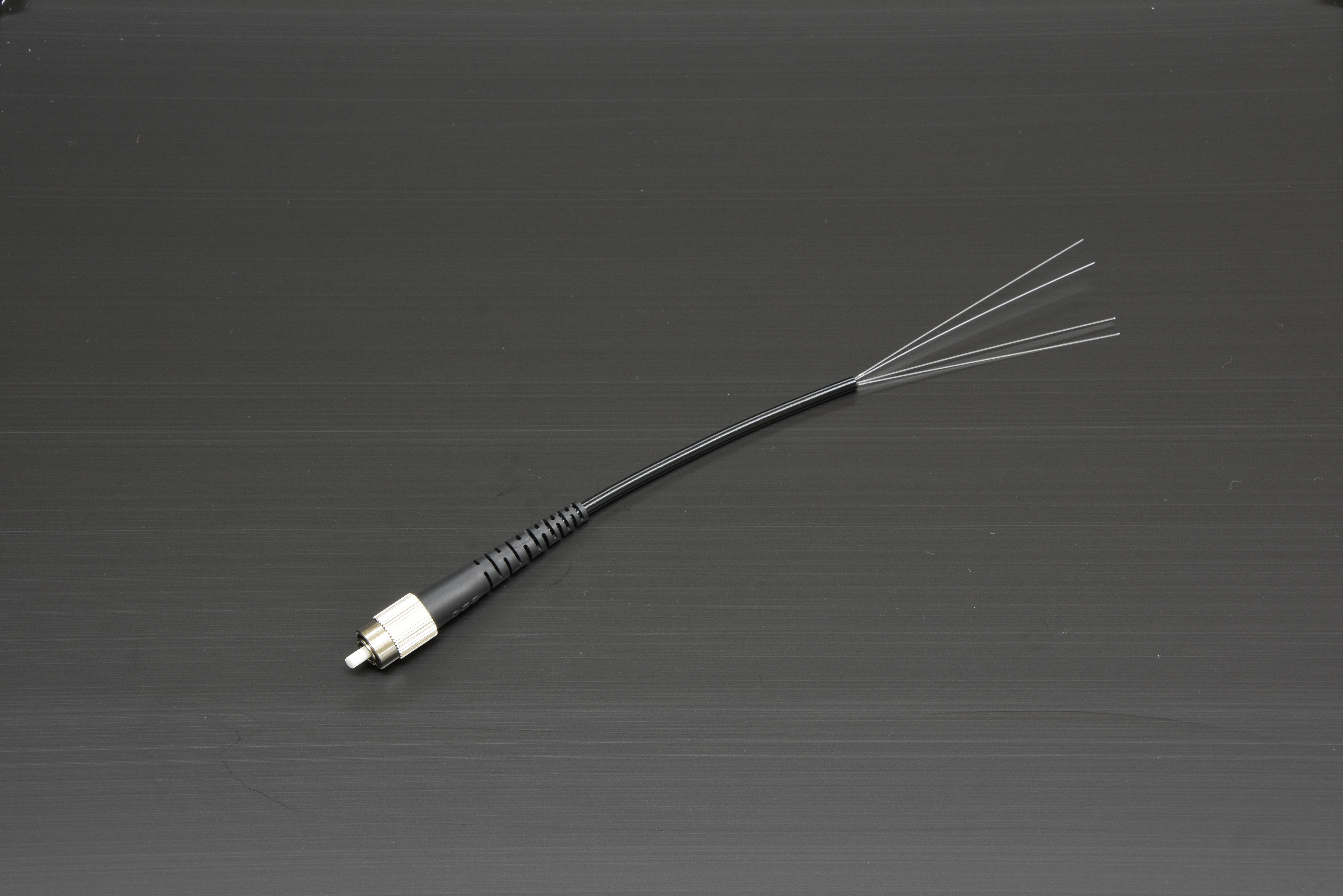

Optical Communication/Fiber Optics

-

Healthcare

continue combining Our strengthsglass microfabrication technology and optical technologies to develop innovative new products and technologies.

Message

As a company developing and manufacturing optical splitter products to fulfill an important role in the social implementation of fiber-to-the-home (FTTH) networks within Japan, we launched our optical device business in 2001 with the construction of a new factory in Shibata Town, Miyagi Prefecture. Ever since that time, we have been developing a variety of different technologies and products under the keyword “optical,” while centering our business operations on the management philosophy of creating value that contributes to society’s prosperity.

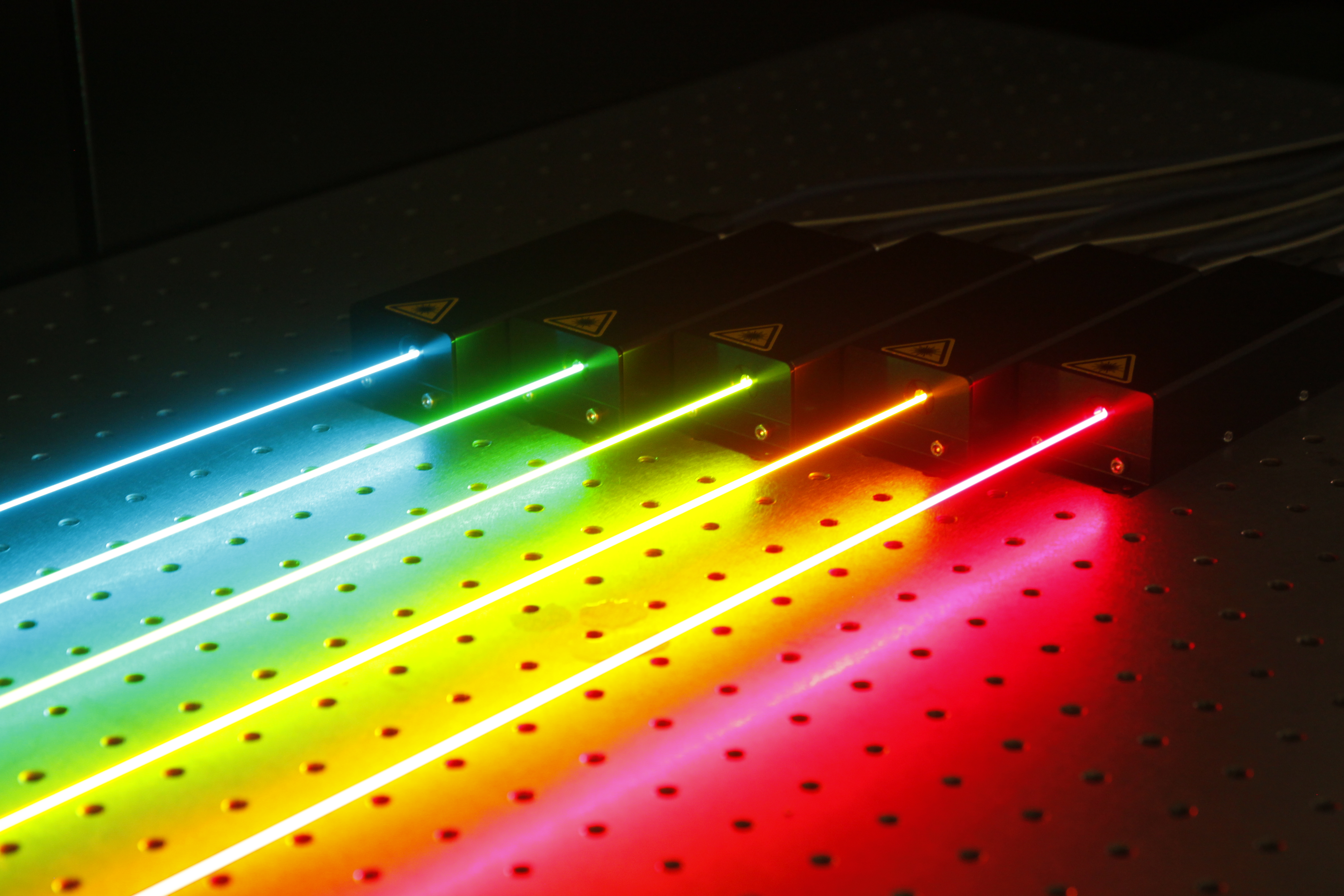

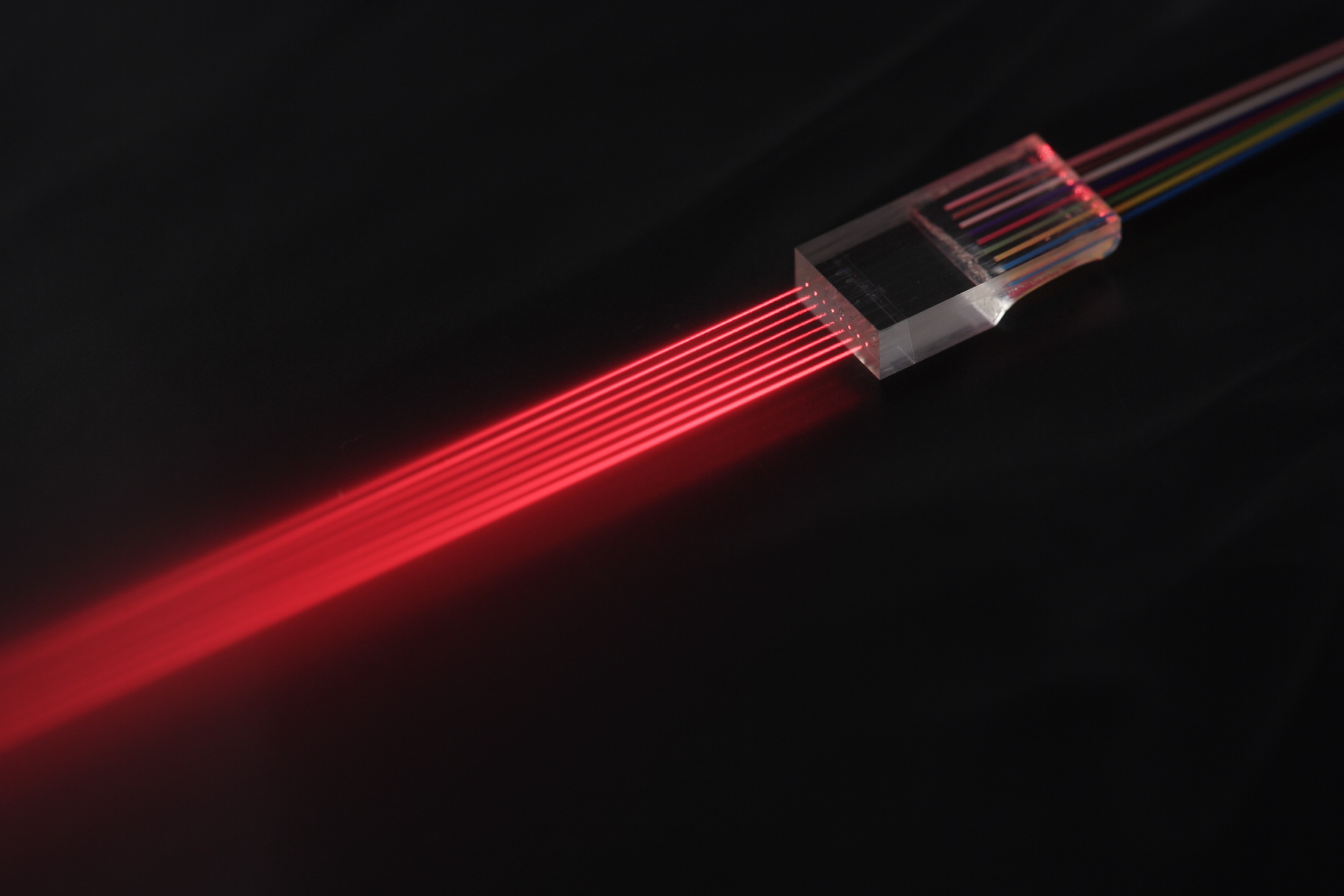

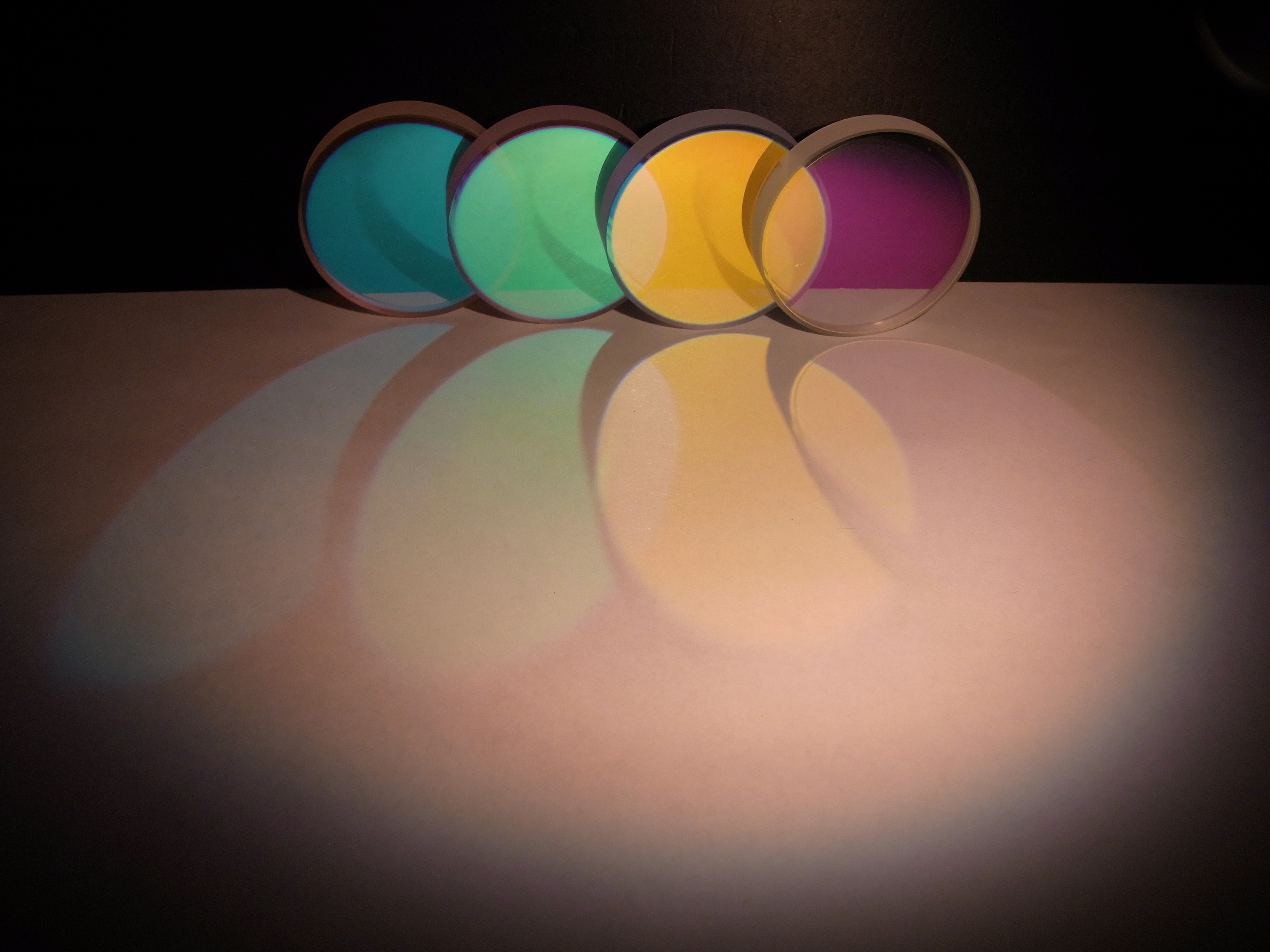

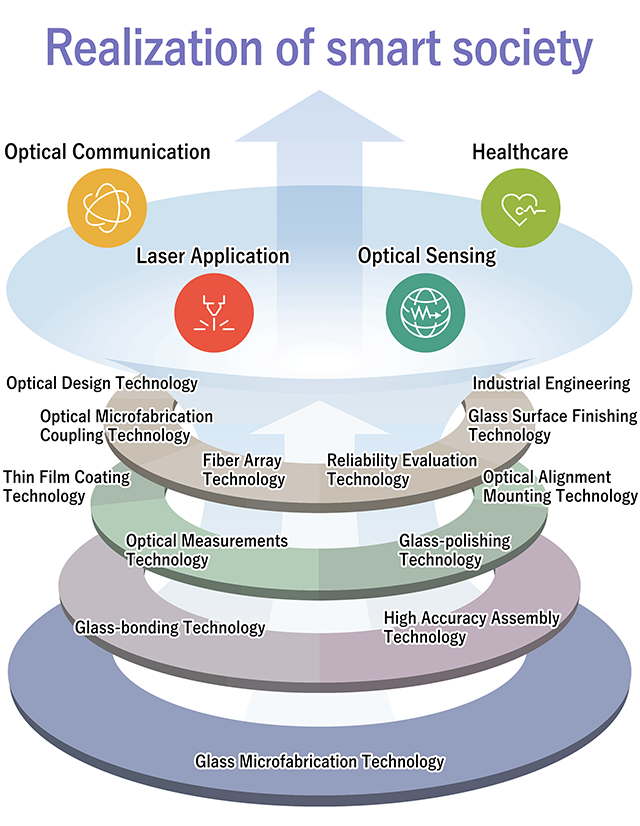

Our company possesses the basic (core) technologies that have advanced to meet not only the domestic level but also the world standards. In addition to the optical and product design technologies to address customer needs, we possess precision optical alignment packaging technology and glass microfabrication technology offering submicron accuracy, glass adhesion and bonding technology to guarantee high product reliability, and thin film coating technology for high difficulty filters with high reproducibility.

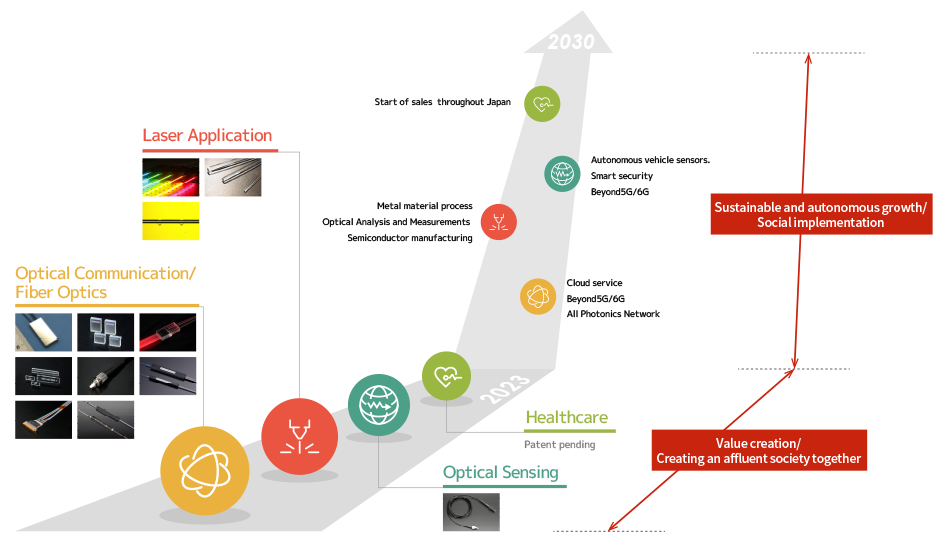

Freely employing these core technologies as competitive strengths, we designated four fields as target business areas for our optical device business: the optical communications field, which is related to the next-generation high-speed communication technology of 5G and 6G, as well as optical communication network development; the laser application field, which is expected to expand and develop as a processing and light source technology; the optical sensing field, which targets advanced optical instrumentation that contributes to self-driving technology and manufacturing; and the medical field, which pursues the interconnections between healthcare and optics. While we expand our solutions business to address customer needs, we will continue to acquire and accumulate new technologies as necessary to resolve these issues.

For the medium-term vision, the Tohoku Electric Power Group adopted the realization of a smart society for a new era originating in Tohoku as the Group’s ideal. As a member of the Tohoku Electric Power Group, we intend to boldly tackle challenges and generate new business while collaborating with other Group companies and tying the results of our expansion activities in the four business fields to the efforts to achieve the Group’s vision—providing comfortable, safe, and reliable services, contribute to carbon neutrality, and undertake SDG initiatives.

Our department’s slogan is as follows: Building a new business base through co-creation. Co-creation means to “jointly create” new value through dialogs with a diverse range of people, including customers, in order to respond flexibly to changes in the times. We will gradually move forward step-by-step by continuing to courageously take on challenges without fearing the advent of a new era. In future, we will continue the efforts to create an organizational culture that enables each and every one of us within the department to realize the potential of both the employees and the organization through the accumulation of our experiences, which then enable us to share our sense of accomplishment with company stakeholders.

Stay tuned for news of our activities moving forward!

Manager, New Business Development Department

February 2023

Technology Platform

Working toward the realization of a smart society by accumulating new knowledge in glass microfabrication, our core technology.

Road map

World-recognized quality and advanced “manufacturing”

Based on proprietary optical fiber processing technology accumulated over many years,Kitanihon Electric Cable Co, Ltd., entered the optical device business.Since that time, the Company built its expertise in the fields of precision optical

In order to maintain submicron-accuracy manufacturing, high accuracy a measurement, and quality,manufacturing is performed in a clean room environment where temperature and humidity are strictly controlled.